Markets

Energy storage

The continuous decline in cost of lithium ion battery over the last decade in addition to advances in Supercapacitor and Fuel cell technologies presents a bright future for Energy storage. However, there are still several challenges regarding charging time, energy density and safety that need to be resolved for mass adoption of energy storage systems and devices. Graphene based electrode materials are the perfect choice for addressing these impediments in the existing energy storage sector, in addition to enabling innovations in this space.

Terracarb’s proprietary technology for Graphene hybridization can enable in development of state-of-the-art Supercapacitors, with high energy density and cycle life. This is possible due to the ultra-high surface area (>1000 m2/gram), enhanced porosity, high purity (<50 ppm ash content) and appropriate doping configuration of Terracarb’s Graphene.This additive is developed to improve the specific capacity, energy density, cycle life and reduce the degree of sulfation and charging time of batteries.

Composites

Terracarb’s Graphene possess high electrical and thermal conductivity, in addition to excellent mechanical and barrier properties. We have performed multi-step structural, chemical and physical characterizations to develop Graphene-based additives, with customized flakes sizes, solvent system and functionalization, catering to the specific needs of the composites industry.

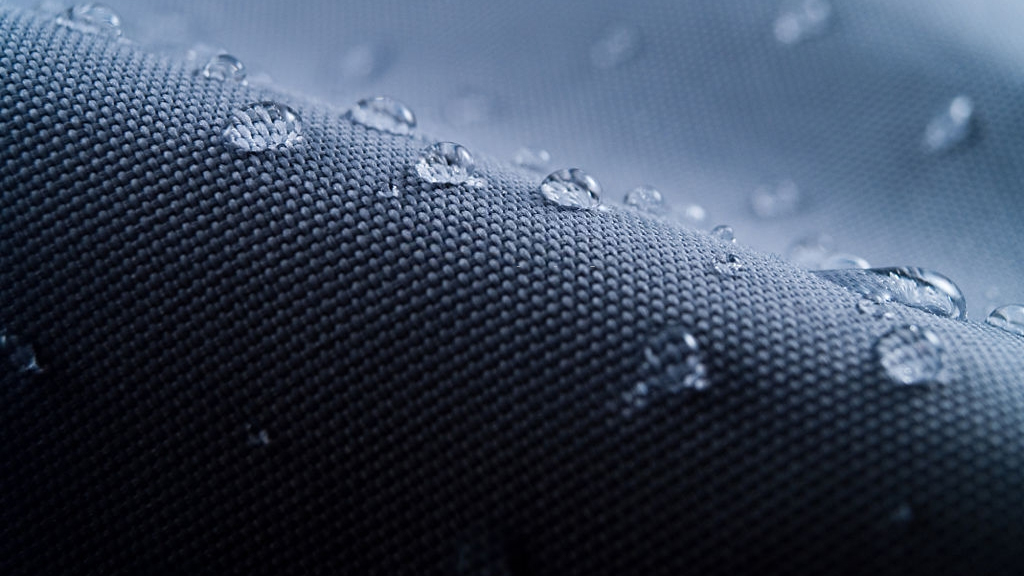

Paints and Coatings

In addition to being used as a coating on metals, Graphene based coating formulations can be used in cellulose based fabrics, leather and plastics. In addition, Terracarb’s Graphene dispersion could be used to design disposable biosensors, with high selectivity and sensitivity.Terracarb’s Graphene based coating products could be readily mixed with paint/coating formulations to also develop ESD products.